Understanding your needs

Testing & QA

Metal testing is a process or procedure used to check composition of an unknown metallic substance.

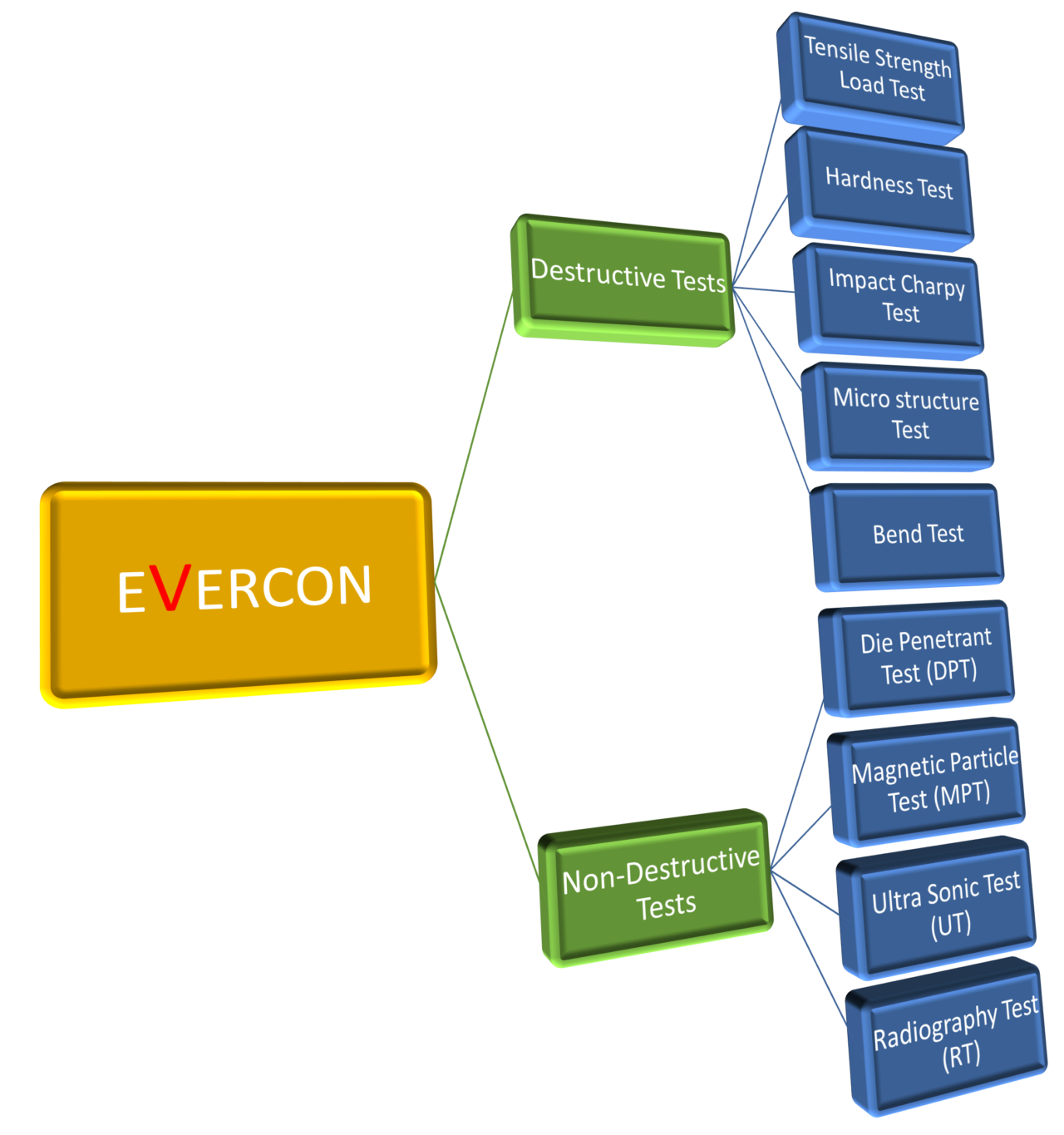

There are destructive processes and nondestructive processes. Metal testing can also include, determining the properties of newly forged metal alloys. With many chemical-property databases readily available, identification of unmarked pure, common metals can be a quick and easy process. Leaving the original sample in complete, re-usable condition. This type of testing is nondestructive. When working with alloys (forged mixtures) of metals however, to determine the exact composition, could result in the original sample being separated into its starting materials, then measured and calculated. After the components are known they can be looked up and matched to known alloys. The original sample would be destroyed in the process. This type of testing is destructive.

Evercon Group has the partner laboratories to perform the Destructive and Non-Destructive Tests under the required environment as per accordance to American Welding Society (AWS) and American Society of Mechanical Engineers (ASME).

However, Evercon and its lab have the capability to do testing according to other standard specifications if required from customers.

The qualifying welders’ codes are the American Society of Mechanical Engineers (ASME) Section IX and American Welding Society (AWS) D1.1.

Committees and subcommittees comprising volunteers in furthering the quality and efficiency of the welding industry work together to develop these codes.

Evercon works with 100% quality checks and assurance for each and every product and project.

Evercon delivers both the test reports, i.e., destructive and non-destructive tests in which destructive includes tensile load test, hardness test, impact Charpy test, microstructure and bend tests. Regarding non-destructive tests Evercon shares the visible report, Die Penetrant Test (DPT), Magnetic Particle Test (MPT), Ultrasonic test (UT) and Radiography test (RT). All the test reports are according to A.S.M.E. standards.

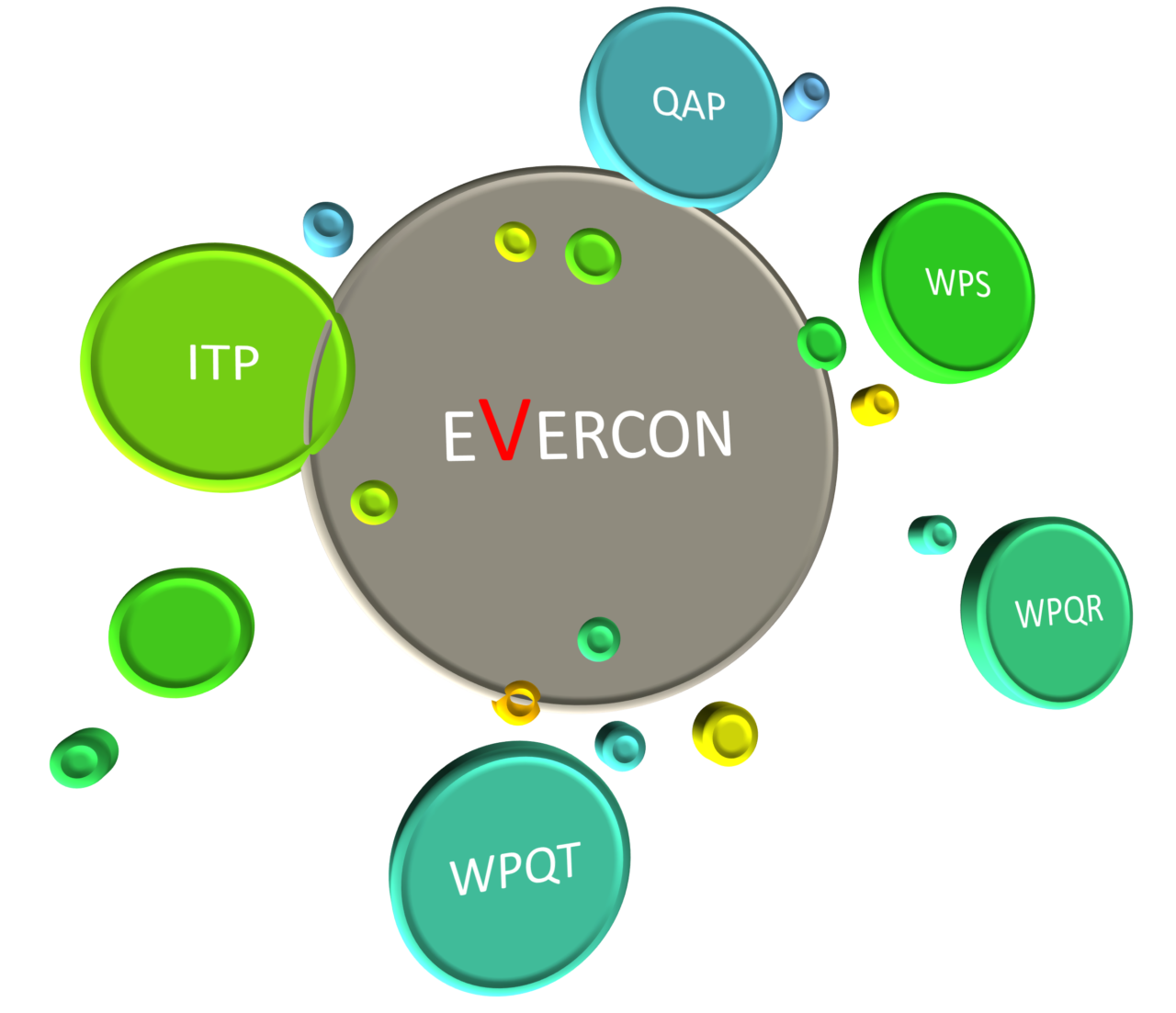

Evercon also follows the Quality Assurance records with 100% effective and maintain the same for each project and shares accordingly whichever is required by the customers. It includes Quality Assurance Plan (QAP), Inspection Test Plan (ITP), Metal Statement to specific customers includes the detail manufacturing process plan, Welding Procedure Specification (WPS), Welding Procedure Qualification Records (WPQR), Welding Procedure Qualification Test (WPQT), Mill Test Certificates (MTC), Welder Operation Qualification Records and the Quality Check sheets & records for every operation controls.

- “Evercon is the Endurance & Quality is Everything”.

Evercon Group has the certified experienced welders and Engineers and fabricators and results the supply of quality proven products include all necessary documents to satisfy the customers in every way and work process flow shall be error free and the ultimate aim is that “if you are thinking of Metal Fabrication Service and Solutions, you are actually thinking of Evercon”.

Journey of Growth and Achievement

Evercon has experienced great growth over the years, but we’ve strived to maintain a family atmosphere where employees can thrive and succeed. Without a doubt, the people behind Evercon are the cornerstone of our company’s success.

- Precision Engineering Solutions for Your Specialized Project Needs.

- Advancing Manufacturing, Tailored Strategies for Your Business Success.

- Premium Quality Services, Priced Just Right for Your Satisfaction.

- Achieving Excellence, Without Compromising Your Budget

- Exceptional Quality, Competitive Pricing - Your Path to Remarkable Results.

- Let us map your path towards significant improvements in productivity.

Tell Us What You Need To Get Done.

Our success is built on strong, personal relationships. Give us a challenge, a budget and

a deadline; we’ll meet them all while maintaining the quality and economy you demand.

Contact Evercon

How can we help

your business?

Are you ready to engage Quality Sheet Metal for your next welding or fabrication project? Feel free to contact us to get started.

Thailand - HQ

Finland

Call Us

+66 (0) 33 683 377

Email us

info@evercon.co.th