Understanding your needs

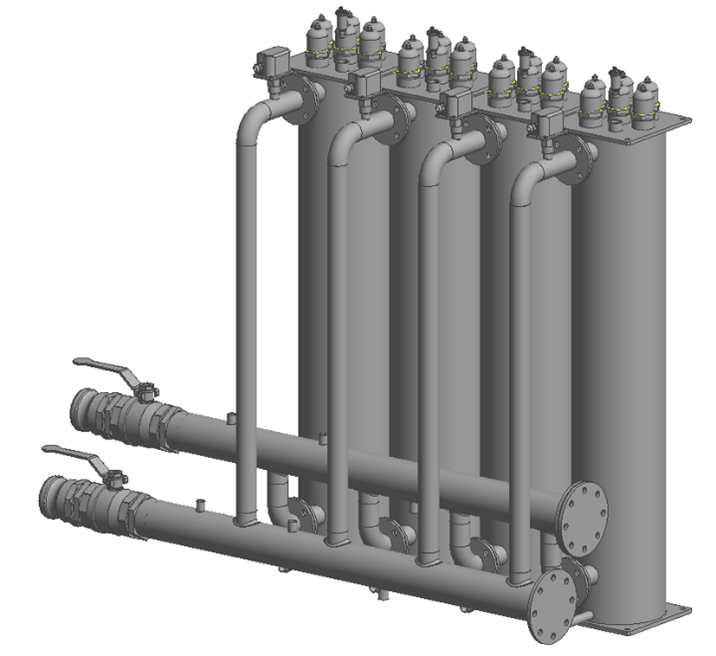

Piping Engineering

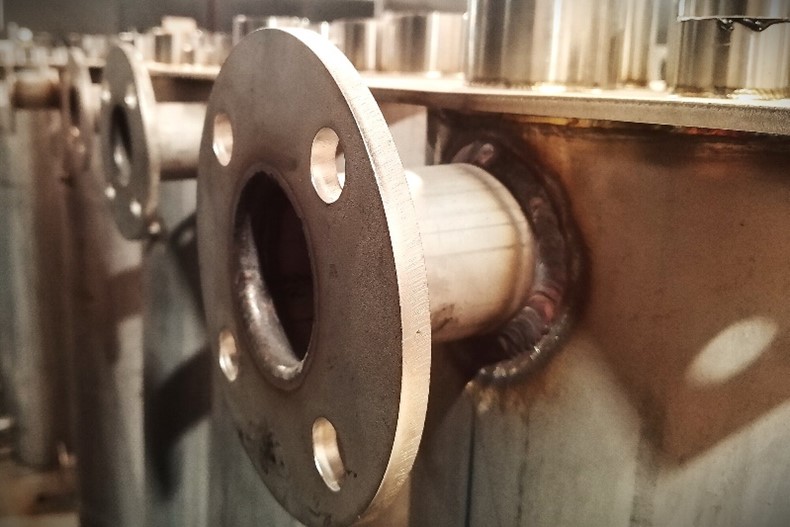

Evercon group has the expertise of providing the service in accordance with ASME B31.3 process piping to its different customers with respect to the joining and welding of piping by submerged arc welding along with the wide variety of joiners either flanged or elbows or in combinations and supply the complex weld joining with 100% quality assured.

We have a team of certified welders and engineers who have huge experience over piping service business and Evercon has the capacity to complete the job service including solutions within the agreed time frame of customers.

What is piping and what are the factors?

The system of pipes together termed as process piping that transport fluids (e.g., fuels, chemicals, industrial gases, etc.) around the industrial segment includes the manufacture of products or in the generation of power. Utility piping systems (e.g., air, steam, water, compressed air, fuels etc.) can also be described in the same that are used in or in support of the industrial process.

Pressure – Temperature Relationship

The pressure rating of the pipe is directly proportional to the temperature of the fluid. The hotter the fluid results the lower the pressure it can hold and thus the higher should be the pressure rating.

Frequently used Pipe Materials

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Galvanized Pipe

- Copper, Brass, Copper Nickel Alloys

- Plastic Piping Systems

Evercon has the experience of supplying service of welding and joining for wide variety of pipe material and 100% quality proven.

Grades

In steel pipe segment, “grade” defines the divisions in which difference in the types are based on carbon content or mechanical properties (tensile and yield strengths).

- Grade A steel pipe has a lower tensile value and yield strength value compared to Grade B steel pipe because it has a lower carbon content. Grade A is more ductile and is better for cold bending and close coiling applications.

- Grade B steel pipe is better for the applications include the factors, i.e., structural strength, pressure, and collapse rate. It is also easier to machine due to the higher carbon content.

Pipe Construction

- By Welding Operation

- Seamless (SMLS)

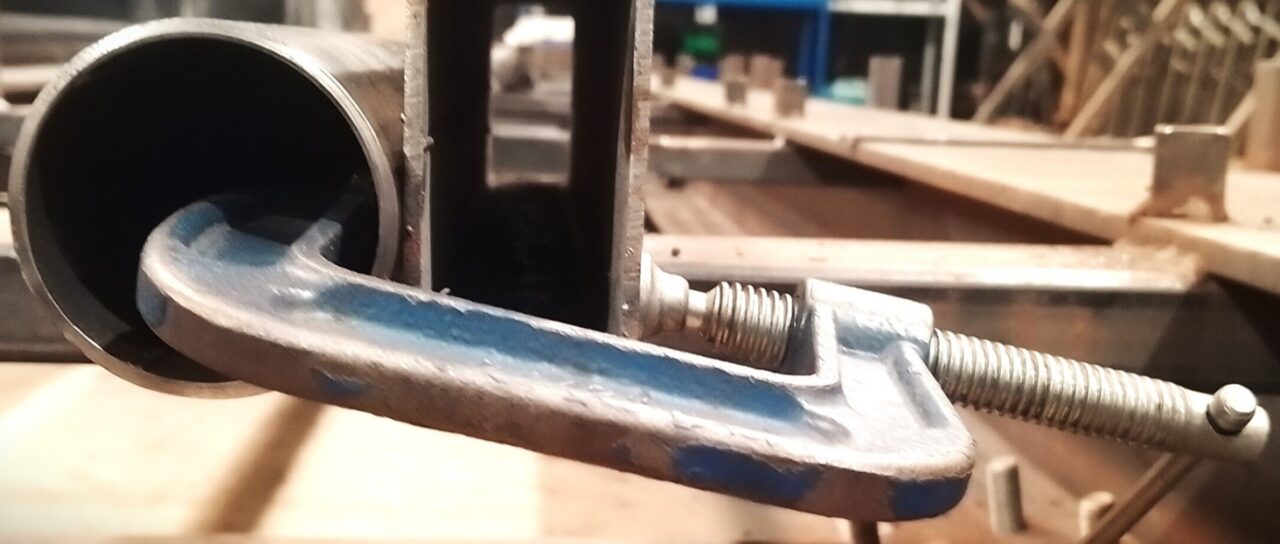

Welding Service and operation is the key strength of Evercon Group as we have 10+ years’ experience certified engineers and certified welders to do most of the types of welding operations and quality proven finishes.

Welding is the major portion of fabrication work and Evercon is an expert of Welding operations.

“Weld & build your life with Evercon. We serve you.”

Pressure Piping Code B 31 was introduced to regularize the manufacture of pipe. In particular, code B31.1.0 assigns a strength factor of 80-85% for a rolled pipe, 60-65% for a spiral-welded and 100% efficiency for a seamless pipe. Generally, wider wall thicknesses are produced by the seamless method. Seamless pipe is usually preferred over seam welded pipe in accordance with reliability and safety. Seamless pipes cannot be substituted whereas ERW and SAW pipes can be substituted.

Welding is the major portion of fabrication work and Evercon is an expert of Welding operations.

Design Factors

Following are the factor with respect to which Evercon works –

Fluid Service Categories (Type) -

Evercon analyzes the type of fluid and pressure to flow through the pipes and accordingly the service has been decided.

Flowrate

Evercon checks the flowrate according to the diameter of the pipeline, wall thickness, theoretical fluid velocity mentioned, and the type of joints required.

Corrosion rate

Evercon checks the fluid type used to flow through the piping system and accordingly the material to consider.

Operating Pressure and Temperature

The operating pressure and fluid temperatures is one of the critical points, Evercon requires from customer end to analyze and understand the requirement for the optimized service and solutions.

Common Codes, Standards and Practices

- ANSI (American National Standards Institute)

- ASME (American Society of Mechanical Engineers)

- ASME B31.1 Power piping (steam piping etc.)

- ASME B31.3 Process piping

- ASME B31.4 Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids and oil and gas

- ASME B31.5 Refrigeration piping and heat transfer components

- ASME B31.8 Gas transmission and distribution piping systems

- ASME B31.9 Building services piping

- ASME B31.11 Slurry Transportation Piping Systems (Withdrawn, Superseded by B31.4)

- ASME B31.12 Hydrogen Piping and Pipelines

- API (American Petroleum Institute)

- ASTM – (American Society of Testing Materials)

- AWWA (American Water Works Association)

- CFR (Code of Federal Regulations)

- EN 13480

- AWS (American Welding Society)

Evercon generally opts ASME B31.3 process piping for the Piping services and solutions because of the following applicable points under B31.3

Piping for all fluid services

Metallic and nonmetallic piping

All pressures

All temperatures

Journey of Growth and Achievement

Evercon has experienced great growth over the years, but we’ve strived to maintain a family atmosphere where employees can thrive and succeed. Without a doubt, the people behind Evercon are the cornerstone of our company’s success.

- Precision Engineering Solutions for Your Specialized Project Needs.

- Advancing Manufacturing, Tailored Strategies for Your Business Success.

- Premium Quality Services, Priced Just Right for Your Satisfaction.

- Achieving Excellence, Without Compromising Your Budget

- Exceptional Quality, Competitive Pricing - Your Path to Remarkable Results.

- Let us map your path towards significant improvements in productivity.

Tell Us What You Need To Get Done.

Our success is built on strong, personal relationships. Give us a challenge, a budget and

a deadline; we’ll meet them all while maintaining the quality and economy you demand.

Contact Evercon

How can we help

your business?

Are you ready to engage Quality Sheet Metal for your next welding or fabrication project? Feel free to contact us to get started.

Thailand - HQ

Finland

Call Us

+66 (0) 33 683 377

Email us

info@evercon.co.th