Understanding your needs

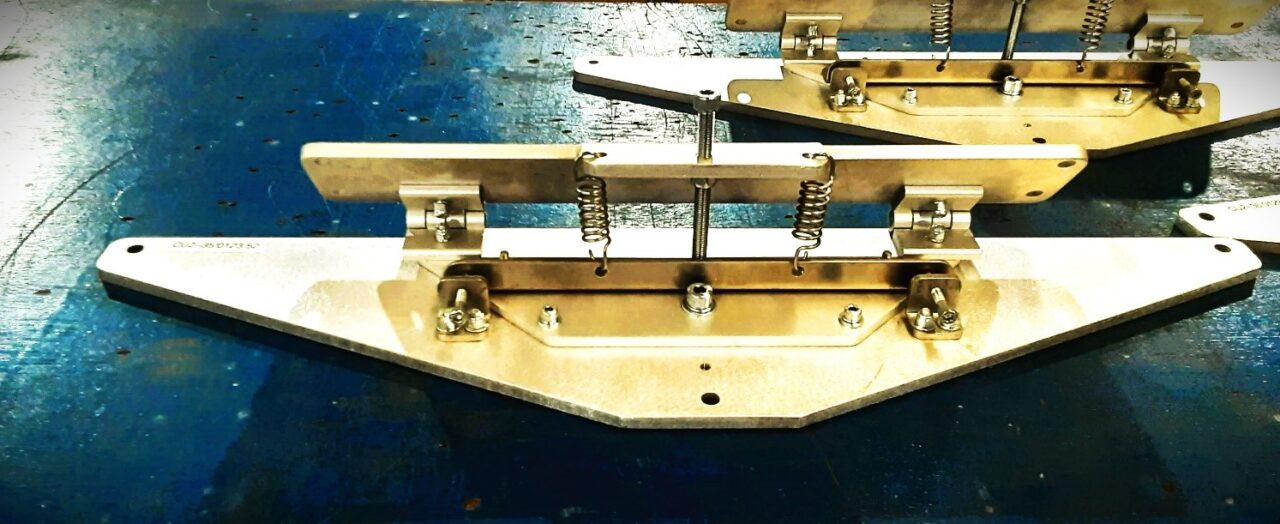

Mechanical Assembly

Evercon group has the capacity and expertise to do the assembly in which our skilled workers and experienced engineers make all necessary check for the alignments, orientation, and positioning of the child parts, semi-finished with respect to fasteners to the correct torque tightened and functionality to make the finished components with 100% quality check.

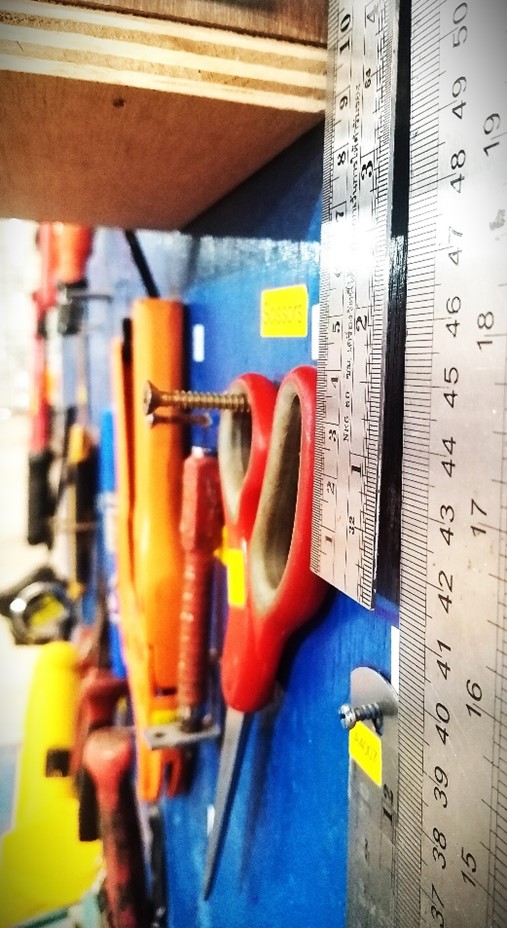

Evercon has 8 assembly stations wherein semi-finished assembly and finished assembly of components used to be done. Every station is equipped with abundant tools and Air-pressure line and Electric point fitments to do the assembly in a faster way with 100% quality finish.

For semi-finished parts of different types of material like woodwork assembly, Evercon is having additional assembly station at Wood section and further in sequence the material travel to main assembly station for further assembly process of final finished goods.

Operators handle all parts and assemblies using motorized vehicles such as forklifts and manual forklifts, without manual trucking. Machines such as overhead cranes perform heavy lifting. Each worker typically performs one simple operation, unless the company.

Evercon equips its tool and assembly stations to handle assemblies ranging from small machine components to 6-ton heavy machinery in a systematic, efficient, and obstruction-free manner.

Evercon is having enough store area to stock the Child parts and semi-finished in accordance to Just-In-Time (JIT) and First-In-First-Out (FIFO) to perform the final assembly in proper sequence and with QC check sheets to avoid any kind of error in assembly processes.

Assembly / Assembly Line / Design for Assembly and Machine Element

Assembly is just the act of combining components in manufacturing or the resulting assemblage. Operators assemble individual parts into semi-finished assemblies and then combine these assemblies to create the final functional component.

An assembly line is a manufacturing process in which workers add parts sequentially to a product to create the final component.

Design for assembly (DFA) is a process by which products are designed with ease of assembly in mind.

- If a product contains fewer parts, it will take less time to assemble, thereby reducing assembly costs.

- In addition, if the parts are provided with features which make it easier to grasp, move, orient and insert them, this will also reduce assembly time and assembly costs.

The reduction of the number of parts in an assembly has the added benefit of generally reducing the total cost of parts in the assembly. This is usually where the major cost benefits of the application of design for assembly occur.

Machine element or hardware refers to an elementary component of a machine.

These elements consist of three basic types:

- Structural components such as frame members, bearings, axles, splines, fasteners, seals, and lubricants

- Mechanisms that control movement in various ways such as gear trains, belt or chain drives, linkages, cam and follower systems, including brakes and clutches, and

- Control components such as buttons, switches, indicators, sensors, actuators and computer controllers.

While generally not considered to be a machine element, the shape, texture and color of covers are an important part of a machine that provide a styling and operational interface between the mechanical components of a machine and its users.

Journey of Growth and Achievement

Evercon has experienced great growth over the years, but we’ve strived to maintain a family atmosphere where employees can thrive and succeed. Without a doubt, the people behind Evercon are the cornerstone of our company’s success.

- Precision Engineering Solutions for Your Specialized Project Needs.

- Advancing Manufacturing, Tailored Strategies for Your Business Success.

- Premium Quality Services, Priced Just Right for Your Satisfaction.

- Achieving Excellence, Without Compromising Your Budget

- Exceptional Quality, Competitive Pricing - Your Path to Remarkable Results.

- Let us map your path towards significant improvements in productivity.

Tell Us What You Need To Get Done.

Our success is built on strong, personal relationships. Give us a challenge, a budget and

a deadline; we’ll meet them all while maintaining the quality and economy you demand.

Contact Evercon

How can we help

your business?

Are you ready to engage Quality Sheet Metal for your next welding or fabrication project? Feel free to contact us to get started.

Thailand - HQ

Finland

Call Us

+66 (0) 33 683 377

Email us

info@evercon.co.th