Understanding your needs

Design and Engineering Support

Design and Engineering is the brain of the body, i.e., of any organization from where the initialization, the thought processes, creativity, design of product starts and that define the functions, forms, and structures together with manufacturing processes.

Evercon designers accomplishes a common goal

Development of new products

Services

From the concept to the embodiment phase, Evercon design and engineering team trying to meet the customers’ actual needs, and eventually to fulfill the business requirement with respect to health, safety, and environment (HSE) constraint.

Evercon Design & Engineering Service include.

- Evercon team provides the theory of the Designs and methodology in accordance with the requirement.

- Evercon has expertise in control panel design and computational support.

- Evercon design and engineered the cable and wire harness assembly and provide the support and service to clients.

- Evercon deliver design optimization and solutions.

- Evercon design team makes continuous coordination with client from the conceptualization phase of the product requirement and realization systems and provide the solution and service accordingly

- Evercon works in Ergonomic and aesthetic design, so that the solution shall be in accordance with human factor requirements.

- Evercon designs product lifecycle and sustainability in accordance with realistic factors.

- Evercon supplied design management and system engineering including service and support.

- Evercon always keeps itself updated with new and emerging engineering design trends and amend the same for the solutions and services.

- Evercon design team supports the manufacturing process design and services.

- Evercon designs the complete machine assembly methodologies, i.e., mechanical, controller, cabling and wire harnessing and support with its continuous service.

- Evercon delivers the offshore support regarding design and operation methodology of the supplied products to different clients around the earth.

The purpose of service design methodologies is to establish the most effective practices for designing services, according to both the needs of users and the competencies and capabilities of service providers. If a successful method of service design is adapted then the service will be user-friendly and relevant to the users, while being sustainable and competitive for the service provider. For this purpose, service design uses methods and tools derived from different disciplines, ranging from ethnography to information and management science to interaction design.

Service design concepts and ideas are typically portrayed visually, using different representation techniques according to the culture, skill, and level of understanding of the stakeholders involved in the service processes. With the advent of emerging technologies from the Fourth Industrial Revolution, the significance of Service Design has increased, as it is believed to facilitate a more feasible productization of these new technologies into the market.

Modeling and Simulation

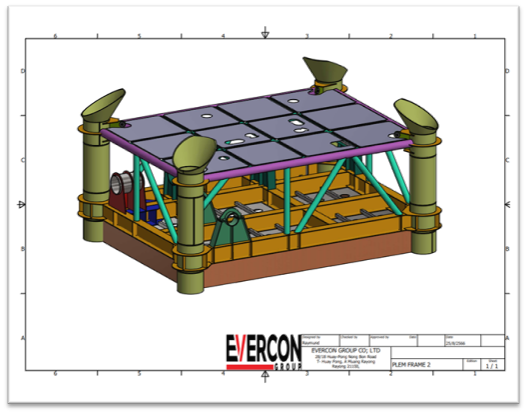

3D modeling is the process of developing a mathematical coordinate-based representation of any surface of an object in three dimensions via specialized software by manipulating edges, vertices, and polygons in a simulated 3D space.

Three-dimensional (3D) models represent a physical body using a collection of points in 3D space, connected by various geometric entities such as triangles, lines, curved surfaces, etc. Being a collection of data (points and other information), 3D models can be created manually, algorithmically (procedural modeling), or by scanning. Their surfaces may be further defined with texture mapping.

Solid

These models define the volume of the object they represent (like a rock). Solid models are mostly used for engineering and medical simulations, and are usually built with constructive solid geometry

Shell or boundary

These models represent the surface, i.e., the boundary of the object, not its volume (like an infinitesimally thin eggshell). Almost all visual models used in games and films are shell models.

Evercon group has the expert designers and modelers who are capable of understanding the real need of the client and initiate the conceptual sketch, modeling, and assembly to propose for the final outcome with optimized solution keeping the business stats’ growth.

- Evercon provides the proposal conceptual general drawings by understanding the need and prepare via sketch, part drawings and assembly combinations.

- SolidWorks 2022, Autodesk Inventor Professional 2024, AutoCAD 2024, Navisworks 2024 are the design software that Evercon uses to initiate the conceptualize phase to embodiment and finish phase.

- Evercon has the skilled draftsmen to complete the proposal with abundant view makes include all the necessary annotations and understanding with respect to surface finish, weld joints, parameters, etc.

- Evercon keeps each and every document filled and filed on a record basis for future references.

- Evercon modelers are maintaining all the revisions in a specific way mentioned in the drawings, so that customer and Evercon understanding will always be on the same platform to bring out the quicker and optimized solutions for the product finalization.

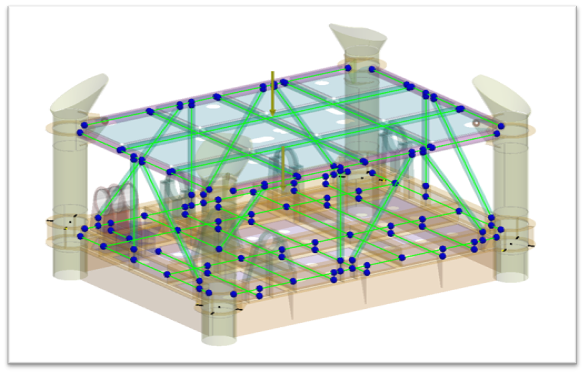

A simulation is an imitative representation of a process or system that could exist in the real world. In this broad sense, simulation can often be used interchangeably with model. Sometimes a clear distinction between the two terms is made, in which simulations require the use of models; the model represents the key characteristics or behaviors of the selected system or process, whereas the simulation represents the evolution of the model over time. Another way to distinguish between the terms is to define simulation as experimentation with the help of a model. This definition includes time-independent simulations.

Simulation fidelity is used to describe the accuracy of a simulation and how closely it imitates the real-life counterpart. Fidelity is broadly classified as one of three categories: low, medium, and high. Specific descriptions of fidelity levels are subject to interpretation, but the following generalizations can be made:

Low

the minimum simulation required for a system to respond to accept inputs and provide outputs.

Medium

responds automatically to stimuli, with limited accuracy.

High

nearly indistinguishable or as close as possible to the real system

A synthetic environment is a computer simulation that can be included in human-in-the-loop simulations.

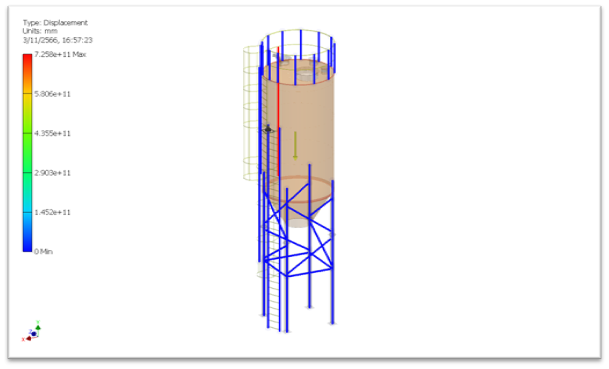

Simulation in failure analysis refers to simulation in which we create environment/conditions to identify the cause of equipment failure. This can be the best and fastest method to identify the failure cause.

Evercon supplies simulation reports to the customers for their better understanding and bring transparency of the solution and services that Evercon proposes. We have experience simulators who are continuously monitoring the manufacturing processes and especially the weldment and weld joint locations to avoid any kind of stress distribution over the section under welding.

The Universal Distribution of Loads (UDL) and Stress Analysis is under monitoring and comparison between actual scenario and computed solution and in continuity till the weld joint and fitment get finished.

Regarding Simulation, Evercon provides –

- Complete Simulation reports

- Comparison chart of actual job work result versus computed solution in software

- The criticality points for understanding

- The bottlenecks of manufacturing processes

Journey of Growth and Achievement

Evercon has experienced great growth over the years, but we’ve strived to maintain a family atmosphere where employees can thrive and succeed. Without a doubt, the people behind Evercon are the cornerstone of our company’s success.

- Precision Engineering Solutions for Your Specialized Project Needs.

- Advancing Manufacturing, Tailored Strategies for Your Business Success.

- Premium Quality Services, Priced Just Right for Your Satisfaction.

- Achieving Excellence, Without Compromising Your Budget

- Exceptional Quality, Competitive Pricing - Your Path to Remarkable Results.

- Let us map your path towards significant improvements in productivity.

Tell Us What You Need To Get Done.

Our success is built on strong, personal relationships. Give us a challenge, a budget and

a deadline; we’ll meet them all while maintaining the quality and economy you demand.

Contact Evercon

How can we help

your business?

Are you ready to engage Quality Sheet Metal for your next welding or fabrication project? Feel free to contact us to get started.

Thailand - HQ

Finland

Call Us

+66 (0) 33 683 377

Email us

info@evercon.co.th