Understanding your needs

Surface Finishing

Finishing is generally the last or final step in the manufacture of components or at the final step of an operation of the component wherein the requirement is the highest quality in terms of accuracy, form, and surface integrity. Fine finishing that will be adding a functionality to the surface of the workpiece to enhance its quality characteristics.

Evercon has the in-house capacity for doing different types of surface finishing operations and supplies high-quality finish goods to its customers.

Finishing technology is used as a value-added manufacturing process to achieve the desired surface quality, geometric form and accuracy. It typically removes a very small amount of material on the scale of a micrometer or less.

Finishing processes basically follows previous material-processing and machining operations. The finishing technology also often encompasses both dimensional control and control of surface integrity including surface texture.

There are many ways of achieving surface finished components such as grinding, sand and grit blasting, buffing and polishing, painting, powder coating, thermal treatment and anodizing.

Grinding

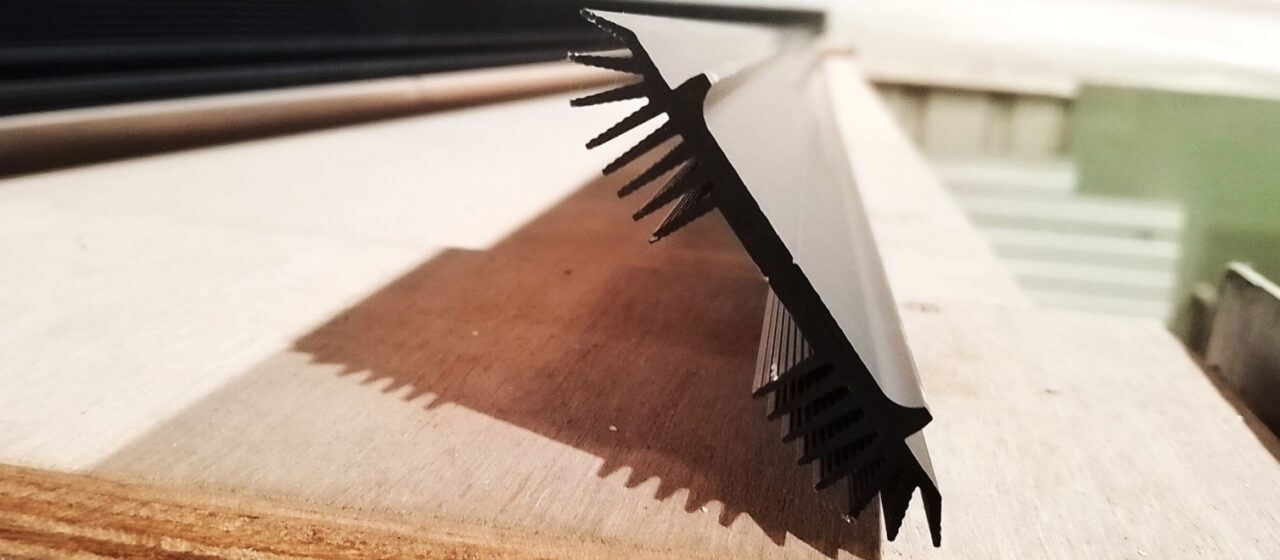

Grinding is the most common form of abrasive machining. It is a material removal process in which the abrasive tool been used whose cutting elements are grains of abrasive material known as grit. These grits have sharp cutting tips, higher hot hardness, chemical stability and better wear resistance.

Evercon adopted different types of grinding process w.r.t. orientation and workpiece and supplied the quality component to end users.

The grits are bonded to give a shape to the abrasive tool.

A grinding wheel implies two types of specification.

Dimensional accuracy

Good surface finish

Sand Blast & Grit Blast

Evercon uses both type of abrasive blasting, i.e., sand blasting as well as grit blasting as per the requirement and client’s specification for finishing.

What is abrasive blasting?

Abrasive blasting is a technique that creating surface textures by the impact of hard particles. Sand blasting, also known as abrasive blasting, uses high-speed solid particles to smooth, shape, and clean hard surfaces. The process works like sandpaper but produces a more even finish and reaches corners and small spaces more effectively.

Sandblasting equipment typically consists of a chamber in which sand and air are mixed. The mixture travels through a hand-held nozzle to direct the particles toward the surface or work piece. Nozzles come in a variety of shapes, sizes, and materials. Boron carbide is a popular material for nozzles because it resists abrasive wear well.

The particles hit a metal surface at high velocity, causing localized plastic deformation. The shape, size, hardness, and speed of the shot particles influence the final surface texture.

Grit blasting is another form of abrasive blasting operation in which solid particles (abrasive material) forced across the workpiece surface at high speed for the process of smoothing, shaping and cleaning the workpiece surface.

Buffing and Polishing

Polishing and buffing are finishing processes for smoothing a workpiece’s surface using an abrasive and a work wheel or a leather strop. Technically, polishing uses an abrasive bonded to the work wheel, while buffing uses a loose abrasive applied to the wheel. Polishing is a more aggressive process, while buffing is less harsh, which leads to a smoother, brighter finish.

A common misconception is that a polished surface has a mirror-bright finish, however, most mirror-bright finishes are actually buffed.

Evercon Group uses the buffing and polishing processes to provide smooth surface to the workpieces produced for the clients.

The removal of oxidization from metal objects is accomplished using a metal polish or tarnish remover; this is also called polishing. To prevent further unwanted oxidization, polished metal surfaces may be coated with wax, oil or lacquer. This is of particular concern for copper alloy products such as brass and bronze.

Evercon uses different types of high-end structure paints as per the client require like-as –

- Acrylic finish paint

- Epoxy zinc rich paint, high build

- Alkyd resin finish paint

- High-solid modified anti-corrosive epoxy polyamide paint

- Acrylic aliphatic polyurethane paint (non-yellowing)

Painting & Coating

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate.

Paints and lacquers are coatings that mostly have dual uses, which are protecting the substrate and being decorative and the paint on large industrial pipes is for preventing corrosion and identification e.g. blue for process water, red for fire-fighting control.

Functional coatings may be applied to change the surface properties of the substrate, such as adhesion, wettability, corrosion resistance or wear resistance.

A major consideration for most coating processes is that the coating is to be applied at a controlled thickness, and a number of different processes are in use to achieve this control, ranging from a simple brush for painting a wall, to some very expensive machinery applying coatings.

Powder Coating

Evercon can supply the finished goods to clients including the powder coat requirement with mentioned RAL codes.

It can be supplied in both requirement whether glossy finish and Matt finish.

What is Powder Coating?

Powder coating uses a free-flowing, dry powder as the coating material. Unlike conventional liquid paint, which manufacturers deliver through an evaporating solvent, operators typically apply powder coating electrostatically and then cure it under heat or ultraviolet light. The powder can be a thermoplastic or a thermoset polymer, and manufacturers commonly use it to create a hard finish that is tougher than conventional paint.

Anodizing

It is an electrolytic process of oxide coating, generally on Aluminum and its alloys.

Evercon uses the anodizing process for the Aluminum profiles for the machine assembly parts with thickness variation of 5 – 25 µm which give improved surface resistance to wear and corrosion.

Journey of Growth and Achievement

Evercon has experienced great growth over the years, but we’ve strived to maintain a family atmosphere where employees can thrive and succeed. Without a doubt, the people behind Evercon are the key of our success.

- Precision Engineering Solutions for Your Specialized Project Needs.

- Advancing Manufacturing, Tailored Strategies for Your Business Success.

- Premium Quality Services, Priced Just Right for Your Satisfaction.

- Achieving Excellence, Without Compromising Your Budget

- Exceptional Quality, Competitive Pricing - Your Path to Remarkable Results.

- Let us map your path towards significant improvements in productivity.

Tell Us What You Need To Get Done.

Our success is built on strong, personal relationships. Give us a challenge, a budget and

a deadline; we’ll meet them all while maintaining the quality and economy you demand.

Contact Evercon

How can we help

your business?

Are you ready to engage Quality Sheet Metal for your next welding or fabrication project? Feel free to contact us to get started.

Thailand - HQ

Finland

Call Us

+66 (0) 33 683 377

Email us

info@evercon.co.th